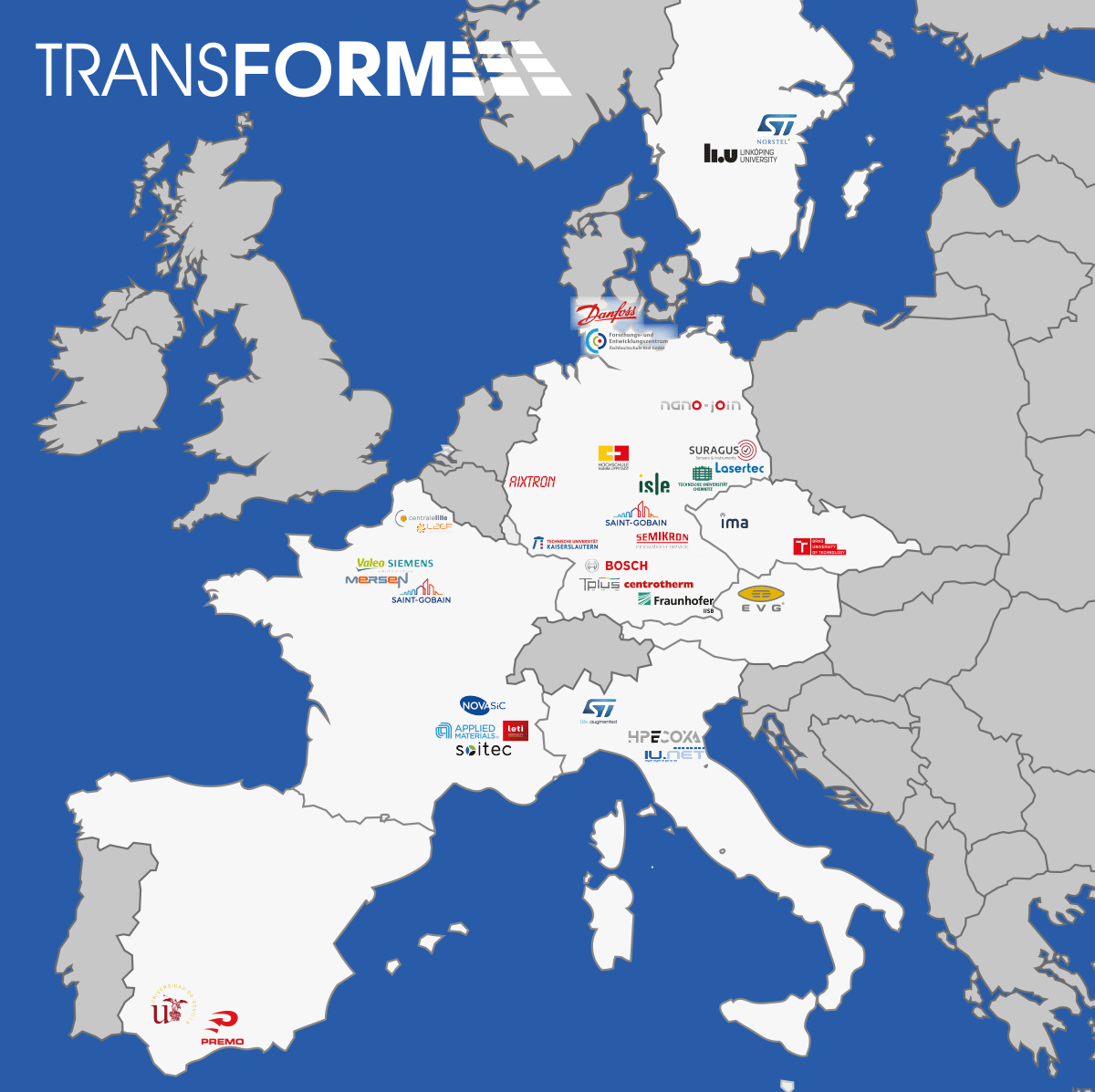

Project Consortium

Partner roles

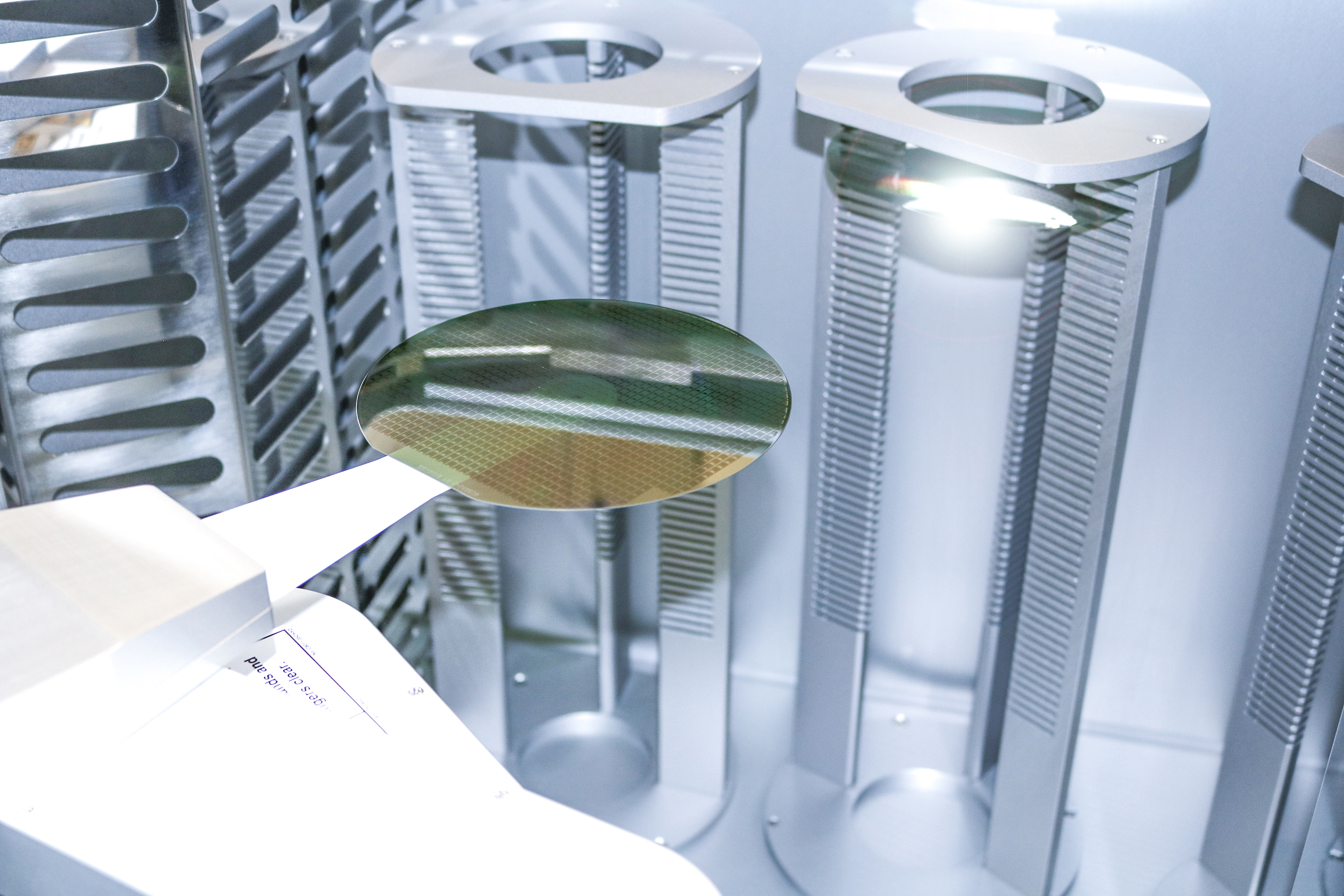

Germany

Germany

France

France

Italy

Italy

Consorzio Nationale Interuniversitario per la Nanoelectronica (IT): Electrical characterization and TCAD modelling of the SiC-based power device reliability and performance, specifications of the converter for the use case “SiC DC/DC converter in agriculture machineries for precision farming application”.

Sweden

Sweden

Austria

Austria

Czech Republic

Czech Republic

Spain

Spain